Poly(2-oxazoline)s: Materials of a new generation

POx, a platform rather than a substitute

A look at the chemistry of poly(2-oxazoline)s (POx) reveals a remarkable versatility that exceeds the properties of conventional polymers such as polyethylene glycol (PEG) by far. POx are produced by living cationic ring-opening polymerization (LCROP), which allows precise control over structure, chain length and functionality. This synthesis method allows targeted variation of side chains, enabling precise tuning of hydrophilic-hydrophobic balance (HLB), thermoresponsive properties, biological interactions and physical and chemical properties. A further advantage of POx is the possibility of specifically modifying the polymer end groups. This end group functionalization allows the incorporation of active ingredients, markers or crosslinkers.

Chemical diversity

The choice of monomers determines the properties of the resulting polymer:

- Hydrophilic variants such as poly(2-methyl-2-oxazoline) (PMeOx) are highly water-soluble and superior to PEG in many biomedical applications.

- Hydrophobic derivatives with aliphatic or aromatic side chains are particularly suitable for the formulation of poorly soluble active ingredients.

- The combination to amphiphilic POx thus enables poorly soluble active ingredients to be introduced into aqueous systems by physical binding.

In addition to the choice of monomer, side chains can be modified or further functional units can be introduced. This results in customized materials for a wide range of applications, from hydrophilic solubilizers and temperature-sensitive thermogels to POx-based hydrogel networks or drug conjugates. In addition, bioactive molecules, fluorescent markers or other groups can be chemically introduced as end groups as well as along the side chains using polymer analogue functionalization.

Self-organization and nanostructures

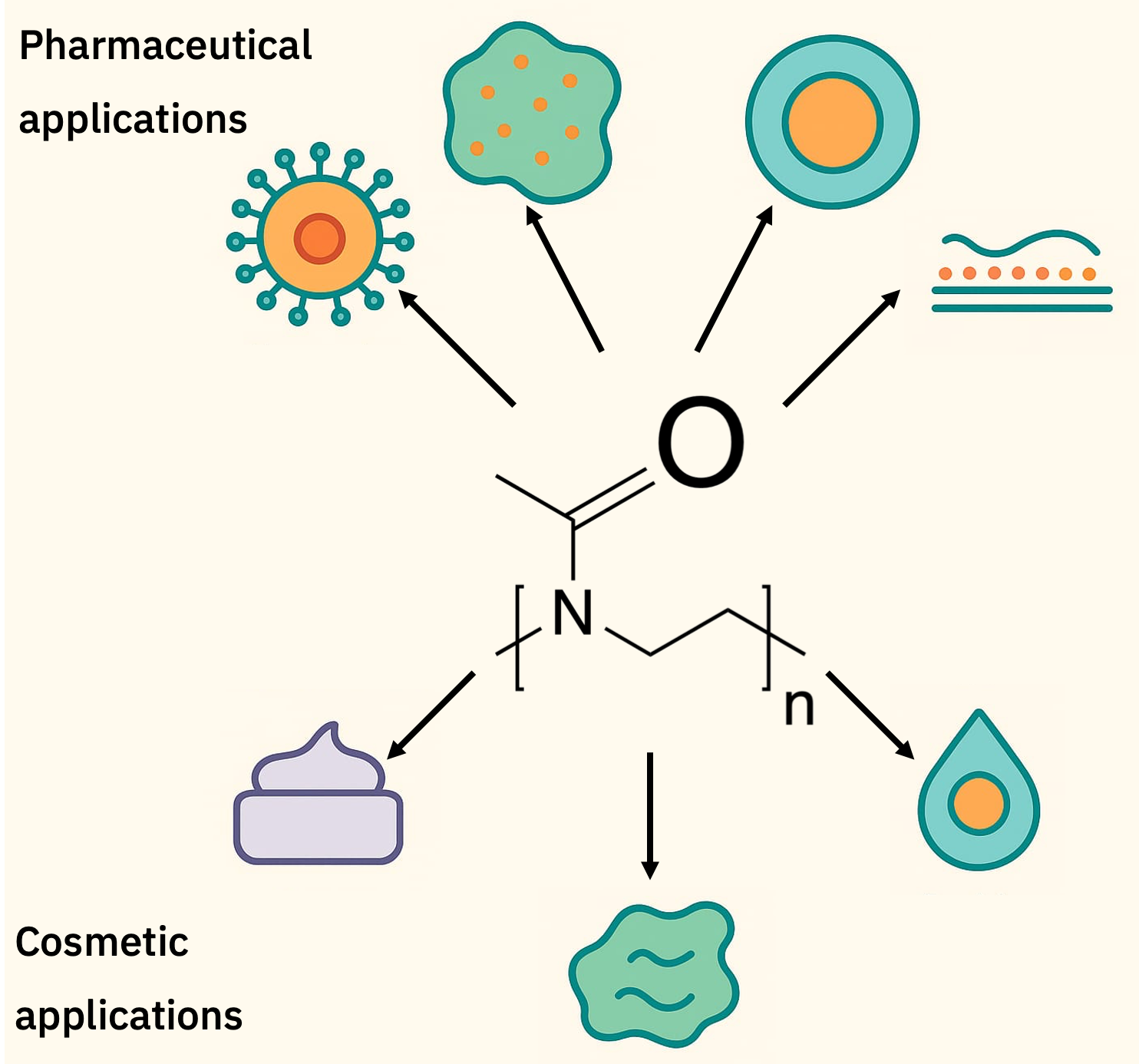

Amphiphilic POx can self-organize in aqueous solution to form nanostructures such as micelles, vesicles or nanogels. These structures are particularly relevant for pharmaceutical applications as they can specifically control the transport and release of active ingredients. The concepts are based on established principles such as those of Ruth Duncan, according to which a balance of stability, release and biological availability is crucial for efficacy.

Biocompatibility: differentiated but convincing

POx, in particular PMeOx and poly(2-ethyl-2-oxazoline), are considered to be well tolerated. Cytocompatibility and hemocompatibility have been proven many times, as has the so-called “stealth” effect, which reduces recognition by the immune system. However, it is important to note that biocompatibility always depends on the structure, composition and end groups and must therefore be tested individually for each application. Current studies are providing an increasingly clear picture: to date, there are no scientific publications documenting systemic toxicity or immune reactions with POx with relevant molecular weights. POx with molecular weights below 60 kDa are excreted renally. After excretion, POx also show better biodegradability than PEG – an important aspect with regard to long-term compatibility and environmental aspects. However, the adaptability of POx means that, if intended, antimicrobial properties can also be generated – an interesting prospect for a wide range of applications.

Stimuli-responsive properties

Certain POx variants react to external stimuli such as temperature, pH value or redox conditions. These stimuli-responsive properties open up new possibilities for intelligent materials, for example for the targeted release of active ingredients or for adaptive systems in diagnostics and sensor technology.

Modularity and industrial scalability

By combining different monomers, initiators and functionalizations, tailor-made POx with defined properties can be produced. The synthesis is not only controlled, but is now also scalable thanks to Oxaphil. Innovative technologies such as those used by Oxaphil mean that POx are now available in industrially relevant quantities and qualities. This makes them suitable not only for research and formulation development, but also for GMP-compliant production of these materials in the future.

Conclusion

Poly(2-oxazolines) are not a replacement – they are an upgrade.

Thanks to their chemical modularity, biological compatibility, physical stability and functional versatility, POx offer a platform for the development of future-oriented materials. Their potential ranges from biomedicine and diagnostics to cosmetics and is far from exhausted.

POx, Materials with effective applications

After an overview of the chemical principles and properties, we now look at specific applications of the materials. The special properties of POx only become fully relevant in practical use. The materials combine functional diversity with high biocompatibility, stability, and formulation efficiency. They have long been established as a powerful class of materials in biomedical research. With Oxaphil, they can now also offer clear advantages in industrial development.

Drug Transport in the Body

One of the first and most widely studied applications of POx is the targeted transport of active ingredients. As already described in Part 1, the materials are hardly recognized by the immune system (cf. Part 1 “stealth” effect) and can self-assemble into structures such as micelles, nanogels, or vesicles. Amphiphilic POx are therefore ideally suited as delivery systems. Both hydrophilic and hydrophobic active ingredients can be efficiently encapsulated and released using POx-based systems. In vivo studies demonstrate longer blood retention times and the absence of immune reactions compared to conventional delivery systems. The functionalization of the end groups opens up additional options for targeted targeting.

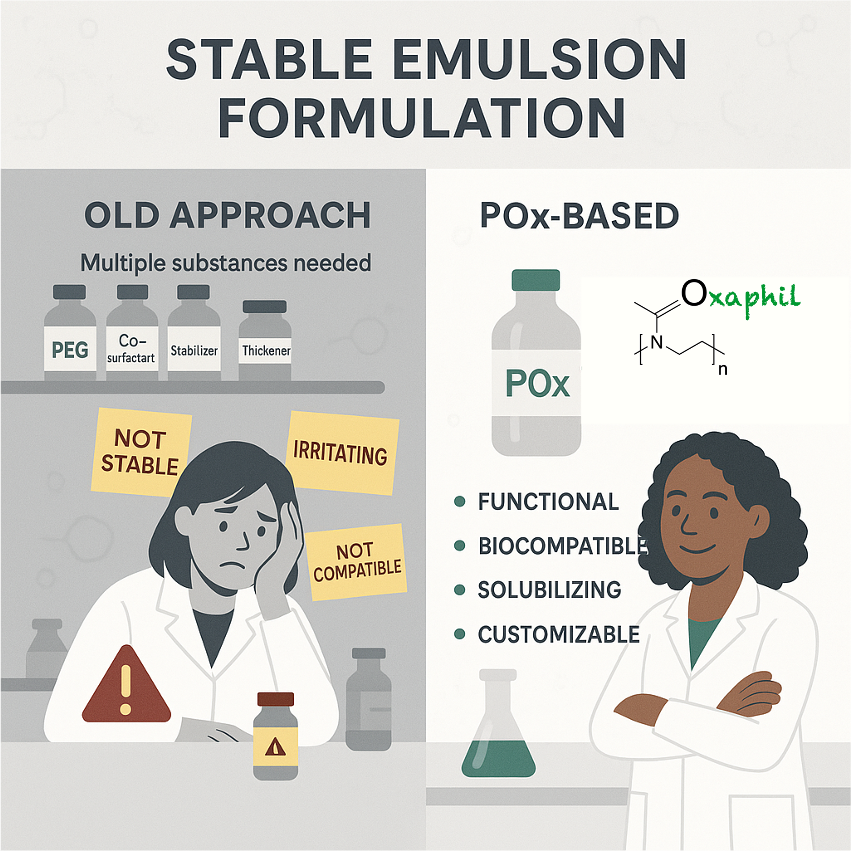

Drug formulation and solubilization

A common problem in pharmaceutical development is the poor water solubility of many active ingredients. POx address this problem and enable stable formulations. Their ability to act simultaneously as solubilizers, stabilizers, and carriers in aqueous systems makes these materials versatile aids in formulation. By carefully selecting the side chains, hydrophobic or amphiphilic polymers can be created that effectively solubilize poorly soluble active ingredients. This opens up new possibilities for various application forms.

Stabilization of liposomes and lipid nanoparticles (LNPs)

With the development of mRNA-based therapeutics, the stabilization of LNPs has become a central topic. Here, too, POx exhibit promising properties. Initial studies demonstrate that POx-coated liposomes exhibit comparable or even higher stability than PEGylated systems. At the same time, the formation of antibody reactions is reduced. In preclinical development, the materials are increasingly being investigated as an alternative to PEG for the stabilization of liposomes and LNPs, especially for repetitive applications.

Surface Modification through Adsorption

The chemical variation of amphiphilic POx allows their physical adsorption on various surfaces, such as metals, plastics, or silicones. Unlike covalently bonded polymer brushes, which are difficult to scale and rarely available as finished products, adsorbed POx layers offer a practical solution for temporary biofilm reduction, antifouling coatings, or improved biocompatibility. Applications range from implant coatings and analytical surfaces to temporary protective layers.

Cosmetic Applications

In the cosmetics industry, there is growing interest in ingredients that are biocompatible, high-performance, and versatile. POx meet these requirements in a unique way. As solubilizers, moisturizers, or structurants, their properties are comparable to established PEG derivatives, while their modular structure opens up new possibilities. Due to their high biocompatibility, the materials offer the potential for improved skin compatibility and more targeted functionality. Their properties allow the stabilization of emulsions, creams, and gels, thus significantly improving texture, shelf life, and sensory properties. Furthermore, they enable the controlled release of cosmetically active ingredients and are suitable for the delivery of sensitive active ingredients such as vitamins, peptides, or plant extracts. Initial concepts demonstrate their suitability in sunscreens, anti-aging formulations, and products for sensitive skin.

A comparison with PEG, which has been used in numerous cosmetic products for decades, highlights the advantages of the POx structure. While PEG has a linear, relatively unvariable chain structure, POx side chains and end groups can be specifically exchanged and adapted. This opens up considerable design freedom for fine-tuning solubility, viscosity, interaction with active ingredients, and sensory properties. This structural modularity allows for the development of formulations that are precisely tailored to the needs of different products and skin types while better addressing regulatory requirements.

It is clear that POx not only improve stability and efficacy in pharmaceutical carrier systems, but that the same logic can also be applied to cosmetic systems. Micelle formation, high stability in complex formulations, and the ability to deliver active ingredients in a targeted manner are properties that also offer significant added value for creams, serums, and lotions. This demonstrates that POx can be considered not only as a functional alternative to PEG, but also as a versatile platform for innovative cosmetic solutions.

Outlook

The diversity of already documented and promising applications demonstrates that POx are relevant not only as an academic concept, but also as a concrete solution to real-world challenges. In an environment where biocompatibility, regulatory safety, and functional precision are becoming increasingly important, these materials offer a new quality for the development of application-oriented systems.

Literature

- T. Lorson et al. – Poly(2-oxazoline)s based biomaterials: A comprehensive and critical update, Biomaterials, 2018, 178, 204-280.

- V. R. de la Rosa, A. van den Bulcke, R. Hoogenboom – Poly(2-Oxazoline)s: The Versatile Polymer Platform for Biomedicine, Material Matters, 2016, 11.3.

- R. Luxenhofer, R. Jordan – Poly(2-oxazoline)s (POx) in Biomedical Applications, Material Matters, 2016, 8.3.

- J. Ulbricht, R. Jordan, R. Luxenhofer – On the biodegradability of polyethylene glycol, polypeptoids and poly(2-oxazoline)s, Biomaterials, 2014, 35, 4848-4861.

- M. Grube, M. N. Leiske, U. S. Schubert, I. Nischang – POx as an Alternative to PEG? A Hydrodynamic and Light Scattering Study, Macromolecules, 2018, 51, 1905-1916.

- M. C. Woodle, C. M. Engbers, S. Zalipsky – New Amphipatic Polymer-Lipid Conjugates Forming Long-Circulating Reticuloendothelial System-Evading Liposomes, Bioconjugate Chemistry, 1994, 5, 493-496.

- R. Duncan – The dawning era of polymer therapeutics, Nature reviews drug discovery, 2003, 2, 347-360.

- Gaertner et al. – Synthesis, biodistribution and excretion of radiolabeled poly(2-alkyl-2-oxazoline)s, Journal of Controlled Release, 2007, 119, 291-300.

- Luxenhofer et al. – Poly(2-oxazoline)s as Polymer Therapeutics, Macromolecular Rapid Communications, 2012, 33, 1963-1969.

- Hoogenboom – The future of poly(2-oxazoline)s, European Polymer Journal, 2022, 179, 111521.

- Zhang et al. – Lipids and Lipid Derivatives for RNA Delivery, Chemical Reviews, 2021, 121, 12181-12277.

- Onugwu et al. – Development and optimization of solid lipid nanoparticles coated with chitosan and poly(2-ethyl-2-oxazoline) for ocular drug delivery of ciprofloxacin, Journal of Drug Delivery Science and Technology, 2022, 74, 103527.

- Simon et al. – Polyoxazolines based mixed micelles as PEG free formulations for an effective quercetin antioxidant topical delivery, International Journal of Pharmaceutics, 2019, 570, 118516.

- Luxenhofer et al. – Structure-property relationship in cytotoxicity and cell uptake of poly(2-oxazoline) amphiphiles, Journal of Controlled Release, 2011, 153, 73-82.

- Tryba et al. – Poly(L-lactide-co-glycolide) membranes modified with RGD-poly-(2-oxazoline) for biomedical application, Engineering of Biomaterials, 2021, 24, 44.

- Tryba et al. – Surface Functionalization of Poly(l-lactide- co-glycolide) Membranes with RGD-Grafted Poly(2-oxazoline) for Periodontal Tissue Engineering, Journal of Functional Biomaterials, 2022, 13, 4.